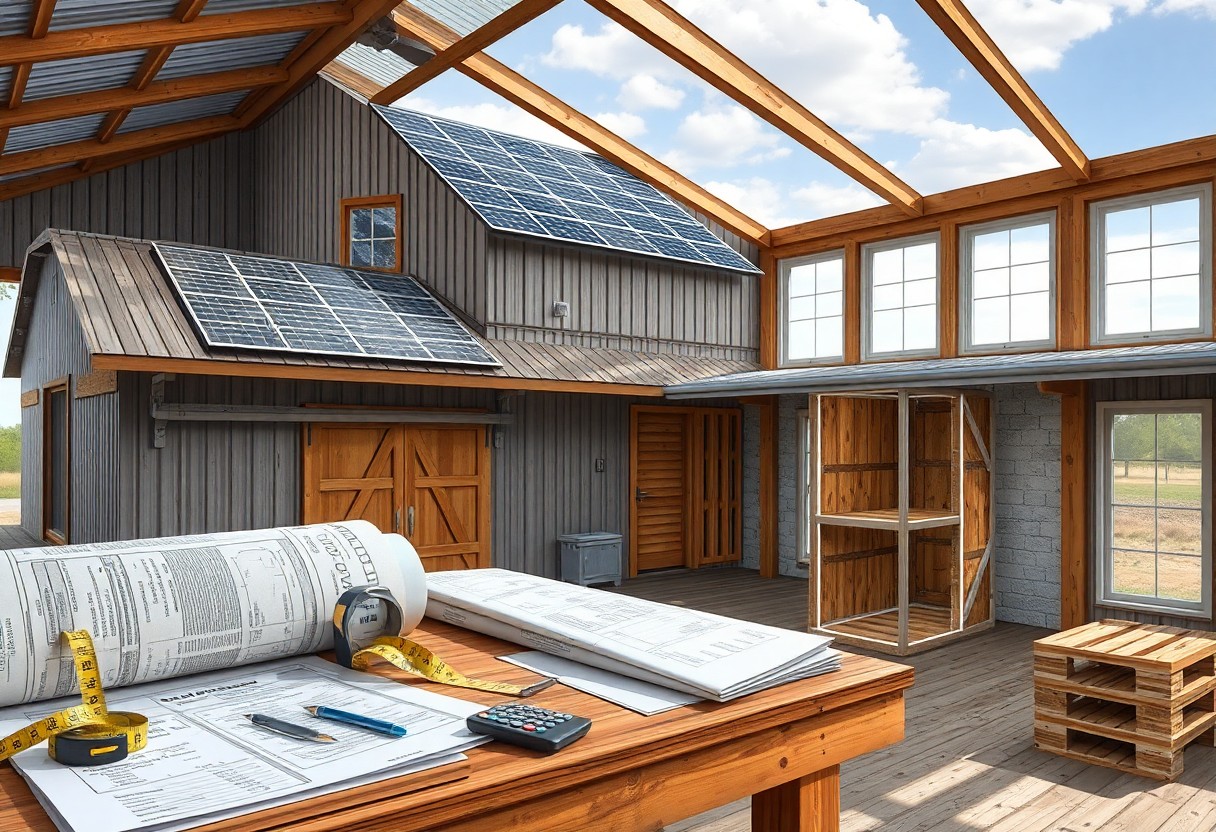

Just prioritize smart design, material choices, and phased construction to lower your barndominium costs without sacrificing quality; you can save by combining efficient layouts, sourcing reclaimed or wholesale materials, negotiating with contractors, doing selective DIY, and investing in long-term energy-efficient systems that reduce future expenses. These strategies help you achieve a durable, attractive barndominium while keeping budgets under control.

Key Takeaways:

- Optimize design and layout to reduce foundation and framing costs-simpler shapes, shared walls, and open plans lower material and labor expenses.

- Choose durable, low-maintenance materials and energy-efficient systems (steel shell, engineered wood, quality insulation, efficient windows) to reduce long-term costs without sacrificing quality.

- Phase the build, obtain multiple bids, use prefabricated components, and handle non-structural DIY tasks to cut labor costs while verifying warranties and contractor credentials.

Understanding Barndominiums

When you evaluate barndominiums, focus on how merging a metal or post-frame shell with residential finishes changes cost drivers: material-heavy exterior shells reduce framing labor, open-plan layouts lower interior partition costs, and shell-first kits can shave months off schedules. Typical sizes run 1,200-3,000 sq ft, build times often 3-6 months, and per-square-foot totals vary widely by finish level, so you can trade higher-performing envelopes for savings elsewhere without sacrificing quality.

Definition and Benefits

You get a hybrid structure-usually a metal or timber shell designed for mixed-use living and workshop space-where benefits include lower framing costs, rapid enclosure with pre-engineered kits, flexible layouts that minimize interior finish area, and potential energy savings when you specify continuous insulation and efficient HVAC; many owners see 10-30% structural savings versus comparable stick-built footprints.

Definition & Benefits at a glance

| Typical shell type | Steel frame or post-frame with metal siding |

| Common sizes | 1,200-3,000 sq ft |

| Build time | 3-6 months (kit + trades) |

| Primary savings | Framing labor, faster enclosure, shared shop/garage areas |

| Energy potential | High with continuous insulation and sealed metal shell |

Cost Comparison to Traditional Homes

You’ll typically pay less per square foot for a barndominium’s structure: reasonable ranges are about $70-$150/sq ft for barndos depending on finishes, versus $100-$250/sq ft for conventional stick-built homes; shell kit costs often run $20k-$60k, and that upfront lower structural expense shifts budget toward interior finishes you control to balance quality and savings.

You can model a specific scenario: a 1,800 sq ft mid-range barndo might total $130k-$270k depending on finishes-shell $30k-$50k, slab $6k-$12k, mechanicals $15k-$35k, interiors $60k-$150k-whereas a similarly sized traditional home often lands 15-35% higher due to stick framing, longer labor, and higher finish-area costs; your choices on insulation R-value, HVAC efficiency, and finish level drive final parity or advantage.

Cost Comparison Snapshot

| Typical shell cost | Barndo: $20k-$60k · Traditional framing: $40k-$100k |

| Avg. cost per sq ft (mid-range) | Barndo: $90-$150/sq ft · Traditional: $120-$220/sq ft |

| Build time | Barndo: 3-6 months · Traditional: 6-12+ months |

| Main variable costs | Finishes, foundation type, HVAC, insulation |

Budgeting for Your Barndominium

Plan for predictable costs and buffer for surprises: allocate a 10-15% contingency and factor soft costs-permits, design fees, site prep-at roughly 8-12% of the build. Use a per-square-foot estimate to gauge feasibility: if your market averages $110-$160/sq ft, a 2,000 sq ft shell will run $220,000-$320,000 before finishes. Track bids to refine your numbers as you go.

Setting a Realistic Budget

Start by defining your target scope, then price shell, systems, finishes, and site separately. Expect shell and systems to consume about 60-70% of construction dollars, finishes 20-30%, and permits/site 5-10%. For example, on a $240,000 project you might allocate $150,000 to structure/mechanical, $60,000 to finishes, and $30,000 to site/fees; update those allocations after three contractor quotes.

Identifying Essential vs. Non-Essential Costs

You should prioritize the envelope, foundation, structural framing, HVAC, plumbing, and electrical-these protect value and typically absorb the largest share of your budget. Defer high-end cabinetry, luxury flooring, and extensive landscaping until after occupancy; those non-important items can be upgraded later or handled piecemeal. Aim to keep discretionary spending under 30% until importants are locked in.

You should audit line items on each contractor bid: compare unit prices for trusses, insulation R-values, window U‑factors, and HVAC tonnage. Balance upfront savings against lifecycle costs-for example, choosing mid-grade windows with a lower U‑factor reduces energy bills over decades. Swapping $3,500 solid-surface counters for $800 quality laminate can free funds to upgrade insulation or install a more efficient HVAC system that saves you 10-20% annually on heating and cooling.

Choosing Cost-Effective Materials

Factor lifecycle costs into every material choice so you avoid cheap short‑term fixes; metal siding can run $2-5/ft² for material only but often outlasts wood and cuts maintenance 30-50% over 20 years, while a simple concrete slab foundation typically takes 8-12% of total build cost-opt for engineered lumber where it saves 10-25% on framing labor and waste, and compare installed vs. material‑only prices before committing.

Durable and Affordable Materials

You can lower long‑term expense by prioritizing durable, low‑maintenance options: standing‑seam metal roofs commonly install for $3-7/ft² and last 40+ years, insulated metal panels improve R‑values and reduce HVAC sizing, and engineered floor joists or trusses reduce onsite labor and minimize waste-use pre‑engineered kits to cut framing time 20-40% and front‑load savings into components that pay back over the building’s life.

Sourcing Materials Wisely

You should pursue multiple supply channels to stretch your budget: buy direct from manufacturers for bulk discounts (often 5-15%), scout contractor closeouts, and compare local mills versus big‑box pricing; ordering materials in palletized batches lowers per‑unit freight, and planning purchases to hit vendor seasonal sales can save you thousands on a typical 2,000 ft² build.

Negotiate terms like returns, delivery windows, and staged shipments so you avoid costly rush fees-pool orders with neighboring builds, use reclaimed elements (windows or barn wood) to cut finish costs 30-50% when labor is available, and get written quotes for lead times to prevent change‑order markups; one builder saved about $7,000 by buying metal panels direct and scheduling deliveries to match the framing pace.

DIY vs. Hiring Professionals

When to DIY

You should take on non-structural, time-flexible tasks like painting, trim, interior doors, sealing concrete, and installing batt insulation to save 20-40% on labor; these tasks require basic tools and reduce contractor hours. For work tied to code or safety-electrical, HVAC, plumbing, foundations, and load-bearing framing-hire licensed pros to avoid failed inspections and costly rework that can exceed $5,000 on a single mistake.

Finding Reliable Contractors

You should shortlist contractors by verifying state licenses, liability and workers’ comp insurance, and at least three local references; request three written, line-item bids and compare timelines. Expect a barndominium shell plus basic finishes to run roughly $80-$150 per sq ft depending on region and materials. Favor contractors with documented barndominium or post-frame experience to avoid learning-curve change orders.

You should also check permit history and past project photos, confirm they pull permits, and require written warranties and lien waivers. Use phased payments (example: 10% deposit, 30% at framing, 30% at cladding, balance on completion), cap change-order rates, and get a clear punch-list process; one owner avoided a $5,200 overrun by insisting on an itemized bid and strict milestone payments.

Design Tips to Save Money

Pinpoint high-impact choices that lower structural and long-term costs: a simple rectangular shell reduces foundation and roof complexity, clustering wet areas cuts plumbing runs, and open plans lower interior framing-choosing a 40×60 rectangle instead of multiple wings can reduce framing and roofing costs by 10-20%.

- Favor compact shapes (rectangles or squares) to cut foundation perimeter and roof edges, which directly lowers material and labor costs.

- Group plumbing and mechanicals-stack bathrooms and kitchens to shorten pipe and duct runs and reduce installation time and parts.

- The orientation and window placement for passive solar reduce heating and lighting loads, cutting energy bills significantly.

Simplifying the Floor Plan

When you simplify the floor plan, you slash framing and foundation expenses-fewer corners mean less lumber and a smaller concrete perimeter; for example, reducing exterior corners from six to four can trim foundation costs by roughly 8-12%. Place bathrooms back-to-back or on a single wall to cut plumbing by up to 20%, and limit interior partition lengths to save on drywall and labor while keeping circulation efficient.

Maximizing Natural Light and Energy Efficiency

You can lower both upfront and operating costs by designing for daylight and thermal efficiency: orient glazing to the south with 15-25% glazing-to-floor-area for passive gain, use overhangs to prevent summer heat, and specify low-E double-pane windows (U‑value ~0.30-0.35) to balance heat loss and gain while reducing electric lighting needs by around 30%.

For more detail, prioritize high R-values and airtightness: aim for R-38 in the roof and R-20 to R-21 in walls (or continuous insulation equivalent) for temperate climates, seal penetrations tightly to get blower-door results near 3-5 ACH50, and use LED lighting plus occupancy sensors to cut lighting energy another 40-75%. Add clerestory windows or light shelves every 12-15 feet to distribute daylight, and plan roof orientation and pitch to accommodate future solar panels for a payback that often falls within 6-12 years depending on local incentives.

Financing Your Barndominium

For financing, you’ll often combine a construction loan with a permanent mortgage, use a construction-to-perm product, or pursue manufacturer/metal-building package financing that accepts 10-20% down. Construction loans typically require 70-80% loan-to-cost, may carry interest-only payments during the build, and use monthly draws tied to inspections. You should budget for 5-10% contingency, show detailed cost breakdowns to lenders, and expect stricter documentation than a standard home loan.

Exploring Loan Options

You can pursue conventional mortgages, FHA 203(k) rehab financing (3.5% down if eligible), USDA rural loans with 0% down for qualifying parcels, or VA loans with no down payment for veterans. Construction loans commonly ask for higher credit scores-often 650-700-and may charge rates 1-2 percentage points above permanent mortgages. Private lenders and hard-money options exist for faster approvals, but they demand larger reserves and higher interest.

Grants and Incentives for Barndominiums

You should hunt federal, state, and local programs that offset costs: the federal solar Investment Tax Credit currently covers about 30% of eligible photovoltaic costs, state energy-efficiency rebates often range from a few hundred to several thousand dollars, and USDA or state rural development programs can offer grants or forgivable loans for low-income or elderly homeowners in rural areas. Check eligibility early to stack savings with your financing plan.

Search resources like grants.gov and the DSIRE database to identify specific incentives in your county; state housing finance agencies and local extension offices often list repair grants, weatherization programs, and property-tax agricultural/use exemptions that can lower operating costs. You’ll want to document timelines and application windows-some energy rebates require pre-approval-so coordinate grant applications with permit and loan milestones to maximize rebates and avoid missed opportunities.

Final Words

To wrap up, you can cut costs on your barndominium by prioritizing durable materials, combining DIY with selective professional labor, standardizing dimensions to reduce waste, shopping auctions and reclaimed resources, and planning efficient systems that lower long-term expenses; consult multiple bids, lock in fixed-price contracts where possible, and focus savings on features that maintain resale value so you don’t sacrifice quality for short-term savings.

FAQ

Q: What are the most effective ways to cut upfront construction costs without sacrificing build quality?

A: Prioritize a simplified, efficient design-open floor plans, standard-sized windows and doors, and fewer interior partitions lower material and labor costs. Use a certified metal building kit or prefab components to reduce onsite labor, and request multiple detailed bids to compare scope and pricing. Value-engineer with your contractor: substitute equivalent, lower-cost materials (e.g., engineered lumber or structural insulated panels) where they won’t affect performance. Bulk-purchase long-lead items, schedule work to avoid costly delays, and hire experienced trades or a good GC to prevent rework. Combining these steps commonly trims 10-25% from initial budgets depending on choices and location.

Q: How can I reduce long-term operating and maintenance expenses for a barndominium?

A: Invest in a well-sealed thermal envelope-high R-value insulation (spray foam or continuous rigid insulation), taped seams, and proper air sealing cut heating and cooling loads. Size HVAC systems correctly and consider heat pump technology for efficient year-round conditioning. Specify energy-efficient windows, LED lighting, programmable thermostats, and low-flow plumbing fixtures. Add durable exterior materials, proper roof flashing, and good drainage to minimize maintenance. Consider solar panels or battery-ready wiring if future electrification is planned. These measures raise upfront cost modestly but lower utility and maintenance bills over the building’s life.

Q: Where is it unsafe to cut costs, and how can I still save without compromising those areas?

A: Do not skimp on the foundation, structural framing, roofing/waterproofing, proper moisture control, or licensed electrical and plumbing work-shortcuts here lead to expensive failures. To save without risking these elements, phase non-structural finishes (flooring, cabinetry) so you can upgrade later, perform cosmetic DIY work if competent, use reclaimed or surplus finishes in low-impact areas, and buy durable but mid-range fixtures that offer long warranties. Secure fixed-price contracts for structural scope to avoid surprise costs, and keep thorough documentation to preserve resale value and warranty claims.