You will find the barndominium lifestyle blends practical, cost-effective construction with flexible, open-plan living, giving you modern comforts and rustic character while optimizing your living space in an efficient structure. With steel frames, wide spans, and adaptable interiors, barndominiums lower building costs and simplify maintenance while enabling energy-efficient systems and strong resale appeal. If you value durability, customization, and a lifestyle that prioritizes space and utility, a barn-style home offers a compelling alternative to conventional houses.

Key Takeaways:

- Cost-effective and highly customizable: barndominiums use simple post-frame or steel shells and open-floor plans, lowering construction costs while allowing flexible layouts for living, work, and storage.

- Durable and energy-efficient when built right: metal exteriors and modern insulation offer low maintenance and long service life, with potential for excellent thermal performance and lower utility bills.

- Appeals to lifestyle and resale markets: the blend of rustic character and contemporary finishes supports indoor‑outdoor living and attracts buyers seeking unique, multi‑use homes, though local zoning and permitting should be checked early.

The Rise of Barndominiums

Definition and Concept

You’ll find barndominiums blend a steel or post-frame agricultural shell with finished living space, often featuring open-plan layouts, 12-20-foot ceilings and integrated workshops or garages. Builders report typical build costs range from $75-$150 per sq ft depending on finishes, letting you prioritize concrete floors and insulated metal panels or luxury interiors. In practice you get the durability of metal framing with flexible layouts that adapt to hobby, business or multi-generational living.

Historical Background

Origins lie in rural American practices of repurposing barns for housing, but the modern barndominium movement picked up after the 1990s when pre-engineered metal buildings became widespread and affordability concerns after 2008 pushed buyers toward alternatives. From about 2010 onward interest surged, aided by regional demand in Texas, Oklahoma and the Midwest and by media coverage showing fast, low-maintenance conversions.

Technological and economic shifts explain the momentum: pre-engineered shells can be erected in 1-2 weeks, while post-frame methods often cut foundation costs and construction time compared with conventional builds. You’ll see manufacturers offering kits and local builders providing turnkey packages, and permit timelines of roughly 30-90 days plus rural financing options frequently determine how quickly a project moves from concept to move-in.

Benefits of Barndomnium Living

You benefit from lower build costs, versatile layouts, and durable low-maintenance materials that suit both family life and workshop needs; metal shells shorten build time so a 2,000 sq ft barndominium can be livable in 3-6 months, and flexible open-plan interiors let you convert bays into garages, studios, or rental units without major structural work.

Cost-Effectiveness

You’ll often spend less per square foot: metal building shells can run $15-$30/sq ft while finished barndominiums commonly total $70-$120/sq ft depending on finishes; for example, a 2,000 sq ft build at $80/sq ft totals $160,000, frequently 10-30% below comparable stick-built homes, plus lower long-term maintenance and simpler additions that protect your investment.

Energy Efficiency

You can achieve strong efficiency with proper insulation and roof choices: reflective metal roofs, spray-foam wall cavities, and tight air-sealing often cut HVAC loads by up to 15-25% versus poorly insulated structures, and integrating rooftop solar is straightforward on large, unshaded metal surfaces to further reduce monthly energy costs.

For deeper gains you should combine closed-cell spray foam (≈R-6.5/inch) or SIPs for high R-values with continuous roof insulation and thermal breaks at metal connections; add balanced ventilation (ERV/HRV), correctly sized HVAC equipment, and a reflective or cool roof coating-projects that routinely drop peak cooling demand and improve year-round comfort while keeping utility bills predictable.

Design Options and Customization

You can adapt a barndominium to match almost any lifestyle, from a 1,200-3,500 sq ft weekend retreat to a full-time family home with a 3-car garage and 800+ sq ft workshop. Common choices include open-plan living, lofted sleeping areas, reclaimed-wood finishes, and energy upgrades – finishing costs typically range $100-$200 per sq ft depending on fixtures. Many owners mix steel framing for durability with warm interior materials to balance budget and barn-authentic character.

Interior Features

If you value spaciousness, plan for 10-16 ft ceilings and exposed trusses that let you add lofts of 200-600 sq ft for bedrooms or offices. Popular interior upgrades include polished concrete or radiant-heated floors, custom kitchen islands with 48-72″ footprints, walk-in pantries, and sliding barn doors to save space. You can also integrate built-in storage, mudrooms for rural gear, and large insulated windows to maximize daylight and efficiency.

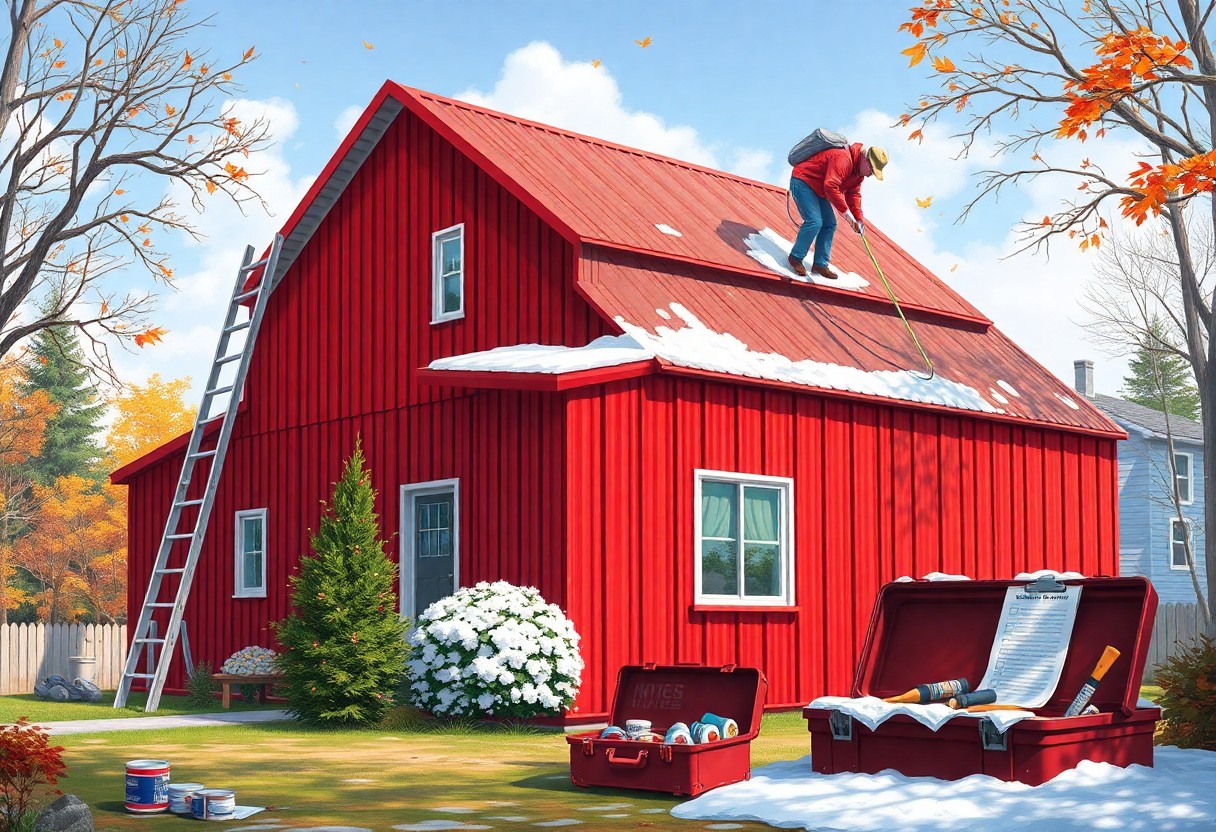

Exterior Styles

When you choose exterior finishes, standing-seam metal, board-and-batten siding, or vertical cedar create distinct looks – metal roofs often last 40-60 years while cedar offers natural texture but higher maintenance. Roof forms vary from simple gable to gambrel for extra loft volume; adding a covered porch or cupola changes curb appeal and outdoor usability. Color, trim, and entry placement let you go modern, rustic, or farmhouse while keeping the barn silhouette.

For a real-world example, consider a 2,200 sq ft barndominium that paired gray standing-seam metal with white board-and-batten accents and a 300 sq ft wraparound porch; the porch added outdoor living without significant structural change, metal lowered long-term maintenance, and cedar accents framed the entry to boost visual warmth. You can similarly mix materials to prioritize lifespan, resale appeal, or low upkeep depending on your site and budget.

Location and Community

When picking where to place your barndominium, prioritize zoning that allows mixed-use and parcels with 1-20 acres to give you workshop, pasture, or rental space; many owners stay within a 30-60 minute drive of a mid-size city to balance services and privacy. You should check county setback rules and septic/utility availability early-those factors often dictate site orientation, build cost, and long-term resale potential.

Popular Areas for Barndominiums

You’ll see the highest concentration in Texas, Oklahoma, and Tennessee, driven by affordable rural land and permissive county codes; pockets in the Midwest (Ohio, Michigan) and the Carolinas are growing too. In Texas Hill Country and around Tulsa, builders report strong demand for 2-10 acre lots, while land prices vary widely-from under $5,000 per acre in some Oklahoma counties to $30,000+ per acre near booming suburbs-so regional research matters.

The Community Aspect

Neighbors in barndominium areas tend to share hands-on lifestyles: you’ll find equestrian facilities, hobby farms, and workshop-minded households nearby, which fosters mutual help on equipment, fences, and emergency access. Social life often centers on seasonal barn events, local farmers markets, and cooperative tool-sharing, so if you value practical camaraderie and shared resources, these communities usually deliver.

Beyond in-person ties, you can tap online barndominium groups and local associations to coordinate bulk materials, permitting tips, and contractor referrals; many owners form informal co-ops for gravel road maintenance or shared hay purchases. If you plan rental income, talk to neighbors about short-term rental activity and septic load expectations, since collective decisions frequently shape local ordinances and property values.

Challenges and Considerations

You should weigh regulatory, financing, and resale tradeoffs: some counties restrict residential use on parcels under 1-5 acres and lenders may classify barndominiums as non‑standard, often requiring 20%+ down or construction/FHA loans. Insurance premiums vary by material and location, and permit reviews commonly take 4-12 weeks in rural jurisdictions, so factor approval timelines and potential added costs into your build schedule and budget.

Zoning and Regulations

You’ll need to verify zoning designations because many municipalities treat barndominiums as agricultural or accessory structures, which can trigger conditional use permits, setback variances, or minimum‑acreage requirements of 1-20 acres. Check septic, well, and floodplain rules, and whether local inspectors demand IRC‑compliant plans or allow agricultural exemptions; plan on 6-12 weeks for approvals and budget $1,000-5,000 for permits and engineering in smaller jurisdictions.

Maintenance and Longevity

You should expect a durable envelope but ongoing maintenance: steel roofs typically last 40-70 years and post‑frame shells resist rot and pests, yet exposed wood, fasteners, and sealants need periodic care. Control condensation with proper ventilation and vapor barriers, inspect roof fasteners every 5-7 years, and plan to reseal or repaint wood trim roughly every 8-12 years depending on exposure.

Dive deeper: in coastal or humid climates install stainless or hot‑dip galvanized fasteners and premium coatings to prevent corrosion-one Gulf Coast owner replaced corroded screws after seven years. Insulate to at least R‑30 in walls and R‑49 in attics, consider closed‑cell spray foam for rooflines to reduce condensation, and set aside about 0.5-1% of replacement value annually for routine upkeep and seasonal checks of gutters, flashing, and sealants.

Case Studies: Successful Barndominium Conversions

Several real-world conversions show how you can stretch a simple shell into an efficient, stylish home: budgets ranged from $95K to $420K, timelines ran 4-12 months, and owners often recouped 15-30% more on resale compared with same-sized conventional homes. These examples focus on scale, cost breakdowns, timelines, and performance so you can benchmark your own project.

Detailed Examples and Outcomes

Below are specific case studies with numbers, materials, and measurable outcomes you can use to plan costs, schedule, and expected benefits.

- 1) Central Texas, 2,400 sq ft post-frame conversion – Shell purchase/erect: $38,000; interior finish & MEP: $142,000; total: $180,000. Timeline: 6 months. Upgrades: spray-foam R-20 walls, mini-split heat pumps, reclaimed oak floors. Result: 28% annual HVAC cost reduction and 18% higher resale vs. local comps.

- 2) Upstate New York, 1,200 sq ft steel-barrel conversion – Shell repurpose: $22,000; insulation, windows, kitchen/bath: $73,000; total: $95,000. Timeline: 4 months. Outcome: short-term rental income of $2,200/month average; payback of conversion cost in ~3 years.

- 3) Central Florida, 3,500 sq ft hybrid timber-frame build – Shell & framing: $110,000; finishes & systems: $200,000; landscaping & garage/shop: $40,000; total: $350,000. Timeline: 9 months. Energy: PV array 8 kW offsetting ~65% of annual electric; net operating cost down 45% vs. nearby stucco homes.

- 4) Midwest farmstead, 2,800 sq ft remodel of existing barn – Structural rehab: $30,000; foundation and utilities: $60,000; interior finishes: $85,000; total: $175,000. Timeline: 7 months. Result: retained heavy timber beams for aesthetics, achieved LEED-like airtightness (0.25 ACH50) after upgrades.

- 5) Pacific Northwest, 1,600 sq ft workshop-home combo – New post-frame shell: $48,000; high-end mechanicals & acoustic treatments: $92,000; total: $140,000. Timeline: 5 months. Benefit: combined live/work zoning increased property value 22% and reduced commute cost/time for owner-operator.

- 6) Southern California, 4,200 sq ft luxury conversion on 5 acres – Steel shell & custom facade: $165,000; high-end finishes, HVAC, solar+battery: $255,000; total: $420,000. Timeline: 12 months. Market impact: listed 12% above comparable suburban homes and sold within 45 days due to acreage plus barn aesthetic.

Conclusion

As a reminder, the barndominium lifestyle gives you affordable, flexible living with open floor plans, high ceilings, and durable steel or wood construction that simplifies maintenance and lowers long-term costs. You can easily customize workspace, storage, and living areas to suit hobby, family, or income-generating needs, while enjoying efficient systems and a stronger connection to rural property-making barn-style homes a practical, modern choice for many homeowners.

FAQ

Q: What exactly is a barndominium and why are they becoming so popular?

A: A barndominium is a residence built from a metal or wood-framed structure that resembles a traditional barn but is finished inside as a modern home. Popularity has grown because they combine affordable, durable shell construction with flexible, open-plan interiors-allowing owners to create combined living, workshop, and storage spaces. Faster build times, lower material costs for the shell, and the appeal of rural or semi-rural lifestyles also drive demand. Many homeowners appreciate the industrial aesthetic, large clear-span spaces for customization, and the ability to integrate income-generating elements like rental suites or home businesses.

Q: How much does it cost to build a barndominium compared to a conventional house?

A: Costs vary widely by region, finish level, and site conditions. Basic metal-shell kits or shells can be relatively inexpensive per square foot, while fully finished barndominiums with high-end interiors, mechanical systems, and site work can approach or exceed conventional construction costs. Typical finished costs often range from moderate to high depending on choices-budget-oriented builds might fall in the lower per-square-foot range, while premium finishes and custom mechanical systems push costs upward. Key cost drivers include foundation type, insulation and HVAC needs, interior finishes, plumbing and electrical complexity, and any special shop or garage equipment.

Q: Are there zoning, permitting, financing, or insurance hurdles to expect?

A: Yes-zoning and permitting vary by jurisdiction; some areas classify barndominiums as agricultural or accessory structures, which can simplify approval, while others require full residential permits and compliance with residential codes. Financing can be more complicated because some lenders and programs prefer conventional stick-built homes; construction loans and conventional mortgages are available but often require thorough appraisals and documentation. Insurance companies may require specific coverages for metal structures or mixed-use buildings. Prospective builders should consult local planning departments, lenders, and insurers early to confirm requirements and avoid costly redesigns.

Q: How do barndominiums perform for energy efficiency, maintenance, and long-term durability?

A: With proper design, barndominiums can be energy efficient and low-maintenance. The metal shell is durable and resists pests and fire better than some materials, but thermal performance depends on insulation strategy-spray foam, rigid board, insulated panels, or SIPs are commonly used to control air leakage and condensation. Without adequate insulation and vapor control, metal buildings can experience temperature swings and moisture issues. Routine maintenance is typically limited to roof and exterior coatings, while interior systems (HVAC, plumbing, finishes) follow typical home maintenance schedules. Prioritizing high-quality insulation, ventilation, and moisture management yields the best long-term results.

Q: How customizable are barndominiums and what planning should homeowners do before building?

A: Barndominiums are highly customizable in layout, scale, and function-options include open great rooms, mezzanines, integrated workshops, large garages, and separate rental units. Early planning should address desired uses (living vs. shop vs. business), structural needs for clear spans, mechanical and plumbing layouts, garage/shop loading and doors, natural light and window placement, and future expansion. Work with designers or builders experienced with metal-frame or post-frame construction to integrate insulation, acoustics, and fire separation into the design. Consider resale appeal and local market preferences when choosing unusual layouts or finishes.