Most homeowners and builders find that choosing the right barndominium kit saves time and money; this guide helps you compare leading manufacturers by price, materials, customization, warranty, and support so you can select the best fit for your site, budget, and design preferences. You’ll get clear pros and cons, delivery and installation considerations, and tips for vetting suppliers to ensure your build meets code and quality expectations.

Key Takeaways:

- Top manufacturers offer complete, customizable kits with quality materials and pre-engineered plans to speed construction and control costs.

- Compare pricing, warranties, lead times, shipping, and local-code support to avoid unexpected expenses and delays.

- Choose providers with strong customer reviews, builder resources, and a network of local contractors to simplify permitting and assembly.

Overview of Barndominiums

What is a Barndominium?

Part barn, part condominium, a barndominium pairs a pre-engineered metal or timber building shell with residential finishes to give you open-plan living plus integrated workspace or storage. You’ll often see sizes from roughly 1,000-3,000 sq ft, with large clear spans that let you place a 1,000+ sq ft shop, garage, or workshop under the same roof as living areas. Kits and custom designs both remain common starting points.

Benefits of Building a Barndominium

You gain lower upfront shell costs, faster construction, and flexible floor plans that suit workshops, hobby farms, or multi-generational living. Typical savings versus comparable stick-built homes range 20-40% on shell costs, build times frequently compress to months, and steel shells offer long service lives-often 40-60 years-while reducing maintenance and allowing large, column-free interior spaces.

For more detail, kits for the building shell commonly range $20,000-$60,000 depending on footprint and gauge, and finished build costs typically vary widely based on finishes and site work. You can tailor a 2,000 sq ft layout to include a 1,000 sq ft shop, open living plan, and loft, cutting duplication of outbuildings and often lowering total lifecycle costs through simpler maintenance and adaptable space usage.

Criteria for Choosing a Barndominium Kit Company

Prioritize firms that score well on material standards, engineering, customization, lead time and after-sales support. You should expect PE‑stamped plans, typical lead times of 4-12 weeks, and transparent warranties (many offer 10-40 year paint or panel warranties). Compare shell-only kit costs (often $20-$60/ft²) versus finished build estimates ($100-$200/ft²), and verify delivery logistics, site-specific engineering, and customer reviews or build photos before committing.

Quality of Materials

Check for Galvalume or G‑90 galvanized panels, commonly 26-29 gauge for roofing/siding, and ASTM‑grade steel for structure; ask for specifications on purlins, girt thickness and fastener types. You’ll want insulation options (R‑13 to R‑30 common) and treated lumber or engineered LVLs where used. Request mill test certificates, paint warranties (20-40 years typical), and sample panels to confirm finish and corrosion resistance.

Customization Options

Assess how freely you can change floor plans, roof pitches, window layouts and bay sizes; many companies allow relocatable interior walls, additional garage bays, or pre‑cut door/window openings for modest fees. You should confirm if clear‑span trusses are available (often up to 60-80 ft) for uninterrupted bays, and whether the vendor provides 3D renders, option packages, and structural revisions for site conditions.

For more detail, verify costs and timelines for specific extras: adding a mezzanine, dormers, upgraded siding, or stamped trusses typically adds 10-30% to the base kit price and can extend lead time by 2-6 weeks. Ask for example builds or case studies showing the exact scope and final cost of comparable customizations, plus any engineering change orders and associated fees so you can budget accurately.

Top Barndominium Kit Companies

Company A Overview

If you prioritize structural strength and quick turnaround, Company A ships 24- or 26-gauge steel kits with engineered plans and a 6-8 week lead time for 1,200-3,000 sq ft models. Their standard package includes R-19 insulation, open-web trusses, and a 12-year structural warranty; typical turnkey estimates range $50-$75 per sq ft, though customization and site prep raise final costs.

Company B Overview

You’ll find Company B excels at high-end customization, offering timber-frame and hybrid steel options, 20-30 year roof warranties, and pricing from $65-$110 per sq ft for fully finished kits. They provide stamped engineering for wind and snow zones, CAD shop drawings, and a 4-6 week quote turnaround for bespoke designs up to 4,000 sq ft.

Beyond basic specs, Company B supports multi-state permitting and has completed case studies-one 2,200 sq ft Mountain build with 50 psf snow-load engineering finished envelope-only in 10 weeks. You can order add-ons like integrated loft systems, custom cupolas, and insulated concrete slab details to streamline your contractor coordination.

Company C Overview

If budget and DIY appeal to you, Company C targets entry-level buyers with pre-cut post-frame kits starting around $18,000 for a 1,000 sq ft shell and 8-12 week delivery. They use 26-gauge panels, standard R-13 wall insulation options, and offer modular bay sizes (20′-40′) to simplify foundation and crane needs for smaller sites.

Company C also provides extensive online build guides and parts-level warranties, which lets you save on labor; typical owner-builder projects using their kits report 6-12 month completion times for finished interiors. You’ll also be able to add pre-wired packages and window/door bundles to reduce subcontractor sourcing.

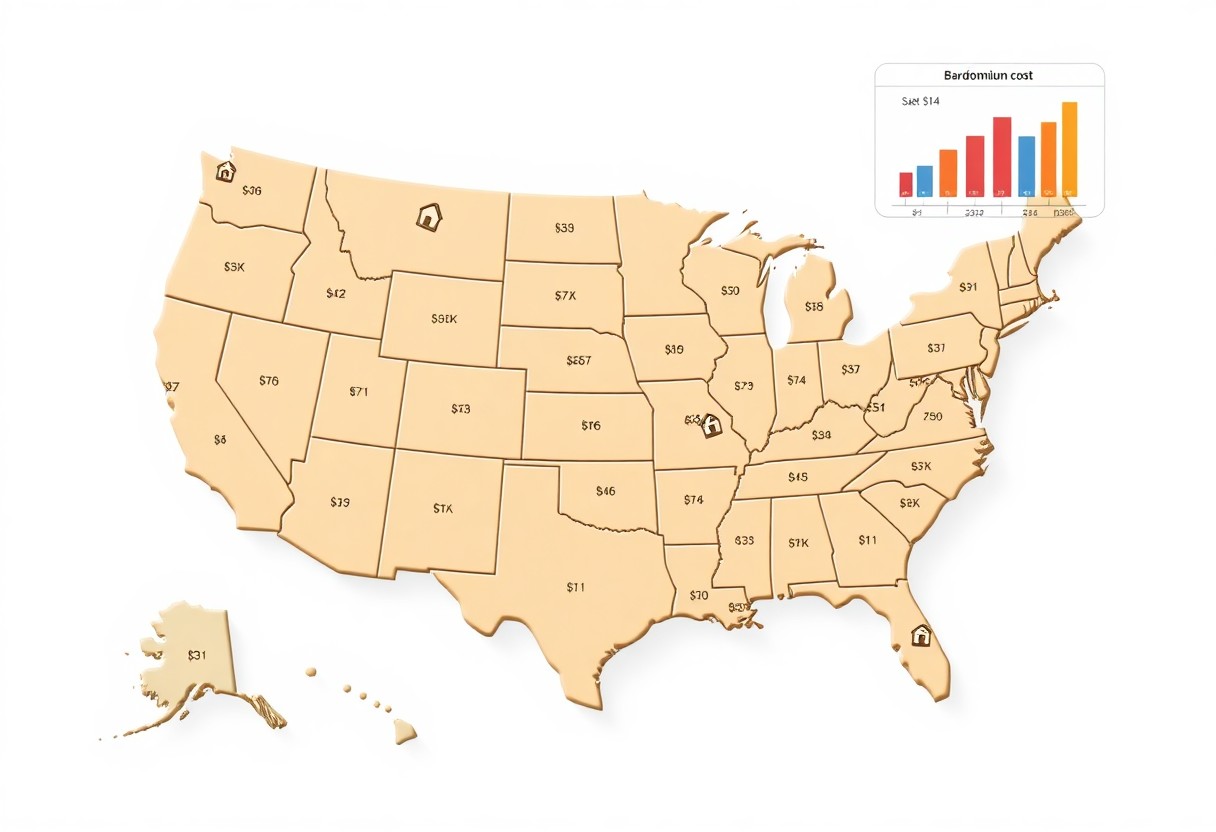

Cost Considerations for Barndominium Kits

Plan on separating kit price from build expenses: basic steel shell kits typically cost $15-$60 per sq ft, while finished barndominiums often land between $70-$150+/sq ft. For a 2,000 sq ft shell you might pay $30k-$120k; foundation, utilities, and finishes can double or triple that figure. You should request itemized quotes and compare delivered kit costs versus turnkey estimates to avoid surprises.

Budgeting Your Build

Break your budget into categories: kit, foundation, site prep, utilities, interior finishes, permits, and contingency. For a 2,000 sq ft project expect foundation costs of $10k-$40k, utility hookups $5k-$30k, and interior finishes averaging $40-$100+/sq ft. You should set a contingency of 10-20% and get multiple bids for each major trade.

Hidden Costs to Consider

Account for hidden line items like soil tests ($500-$2,000), crane or delivery fees ($1,000-$5,000), septic hookups ($5k-$20k), upgraded footings for frost or expansive soils, HVAC upsizing and permit or impact fees. You should ask kit sellers what they exclude so you can budget accurately.

In one build, a homeowner bought a $45k kit for 1,800 sq ft but paid $28k for slab reinforcement due to clay soils, $9k for septic, $6k to extend power, and $15k for insulation and finishes-add-ons exceeded the kit cost. To limit exposure you should get a site evaluation, line-item quotes from the supplier, and at least two foundation bids.

Customer Reviews and Testimonials

Customer feedback across review sites highlights repeatable patterns you can use when vetting kits: many buyers give average ratings between 4.2-4.8/5, cite rapid shell erection and durable 24-26 gauge steel, while service responsiveness and warranty follow-through separate top firms. You should weigh quantified praise-like multiple reports of 2-4 day shell assemblies for 2,000-2,500 sq ft kits-against the frequency of negative notes about shipping or paperwork.

Positive Experiences

Many owners tell you that prefab kits significantly cut framing time-Company A customers reported completing the structural shell on a 2,400 sq ft build in 3 days with two experienced crew members; customer-service response times of 24-72 hours and documented 20-year roof warranties are common selling points. You’ll also find case studies where turnkey engineering reduced permit cycles from months to weeks, saving both time and carrying costs.

Common Challenges

Shipping delays and missing components show up regularly in critical reviews: buyers report lead-time slips of 4-12 weeks during peak seasons and roughly 8-12% of complaints reference incomplete fastener packs or unclear installation details. You should expect some punch-list items and plan contingency time and budget-multiple reviewers noted spending an extra $1,500-$5,000 resolving parts or plan-interpretation issues.

To mitigate these problems you can insist on written lead times and itemized packing lists, inspect deliveries within 48 hours and photograph shortages, and order 10-20% extra consumables up front. Also verify that stamped engineering matches local code before purchase, keep all communication logged for warranty claims (many require notice within 30 days), and consider hiring a local erector familiar with barndominium specifics to close punch-list items faster.

Tips for a Successful Barndominium Build

Sequence your build to reduce delays: order the foundation and shell to overlap, lock in a 24- or 26‑gauge steel kit with typical 8-12 week lead times, and separate kit cost from finish work (concrete slabs average $4-8/sq ft; insulation $1-3/sq ft).

- Obtain stamped plans and permits before materials arrive

- Secure three bids and written start dates for trades

- Preorder long‑lead items like windows and HVAC

Recognizing preordering key components can shave weeks off your schedule.

Planning Your Space

Start by mapping daily flows: if your shell is 2,400 sq ft, consider allocating about 1,800 sq ft to living and 600 sq ft to workshop or storage; aim for 10-14 ft ceilings in primary spaces, cluster plumbing within a 20‑ft run to save $3,000-6,000, and plan a 3-4 zone HVAC layout so you don’t oversize equipment for a 2,000-3,000 sq ft layout.

Working with Contractors

Require at least three written bids, verify licenses and insurance, and prefer fixed‑price or GMP contracts to limit surprise costs; expect contractor markup of roughly 10-20% above subcontractor rates, a shell erection timeline of 8-12 weeks, and total build time of 4-6 months for a typical 2,000-3,000 sq ft barndominium.

Insist on a clear payment schedule (common draws: 10% deposit, 30% after foundation, 40% after shell, 20% at completion), written change‑order procedures with a 10‑day response window, lien waivers, and a minimum one‑year workmanship warranty; also visit at least three past projects and request a schedule of values before signing.

FAQ

Q: What should I consider when choosing a barndominium kit company?

A: Evaluate company reputation, product types, and the level of engineering and support they provide. Key factors include: quality of materials (gauge of steel, treated timber, fasteners), availability of stamped structural drawings for your jurisdiction, customization options for floor plans and exterior finishes, warranty terms, delivery logistics, and on-site assembly assistance or certified erectors. Compare real customer reviews and completed projects, verify lead times and shipping costs, confirm any required foundation or concrete scope, and check whether the company offers financing or works with lenders. Ensure the company’s kit aligns with local building codes and that you have access to reliable local contractors for plumbing, electrical, insulation, and interior finishes.

Q: Which barndominium kit companies are commonly recommended and what sets each apart?

A: Several manufacturers are frequently recommended for different priorities: Morton Buildings – strong custom design capabilities and a nationwide dealer/installer network for turnkey projects; Legacy Building Solutions – competitive pricing on post-frame and pole barn-style kits with good customization; Armstrong Steel – heavy-gauge engineered steel buildings suited to durable steel shells; SteelMaster Buildings – bolt-together steel kits that simplify DIY erection and reduce erection time; General Steel – commercial-grade pre-engineered buildings with robust engineering documentation; American Barn Company / Homestead-style builders – options that blend traditional barn aesthetics with residential finishes. Match the company to your priorities: full-service custom design, budget-friendly kits, DIY-friendly systems, or commercial-grade engineering and warranties.

Q: What are typical costs, timelines, and best practices for managing a barndominium kit build?

A: Costs vary widely: basic shell kits often range from about $20,000 to $100,000+ depending on size and materials; finished barndominiums commonly fall between roughly $80-$200+ per square foot depending on finishes, systems, and labor. Timeline: ordering and fabrication typically takes 4-12 weeks, site prep and foundation can take 2-8 weeks, shell erection often completes in a few days to a few weeks, and full interior build-out can take several months. Best practices include securing stamped plans and permits before ordering, budgeting a contingency of 10-20% for change orders and unforeseen issues, coordinating the foundation contractor with the kit delivery window, hiring or consulting with an experienced general contractor familiar with metal/post-frame builds, confirming insulation and HVAC strategies early, and documenting warranty and post-delivery support terms. Factor shipping, crane or rigging costs for erection, and local utility hookups into your schedule and budget.